High Density Relays Modules

High Density Relay Modules

for locomotive’s auxiliary power circuits

Mors Smitt has delivered 40 High Density Relay Modules (HDRM) to an important European train manufacturer: 20 modules for safety D relay and 20 modules for control. In the coming 2 years we expect 60 more panels. These onboard relays panels will be implemented in the new generation locomotive (for passenger and freight transport), designed with both an electric and a diesel-electric drive. That means that it can be used on both electrified and non-electrified railway lines. The locomotives are built in Europe.

Challenges

If all or even a few motors are started simultaneously, it would cause a tremendous demand on the power supply in terms of current drawn. This might cause the power supply to trip.

Solution

To prevent such a situation, starting of some of the motors is staggered which prevents heavy load currents being drawn. The sequential starting of auxiliary machines is done with relays logic.

Each locomotive will be equipped with two HDRM panels:

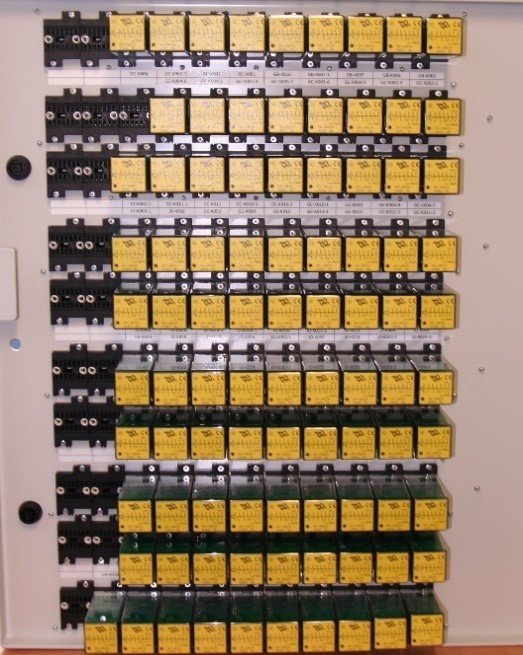

- One modular panel with up to a staggering 90 D6-U safety relays, freely configurable, with 540 contacts.

|

|

.png) |

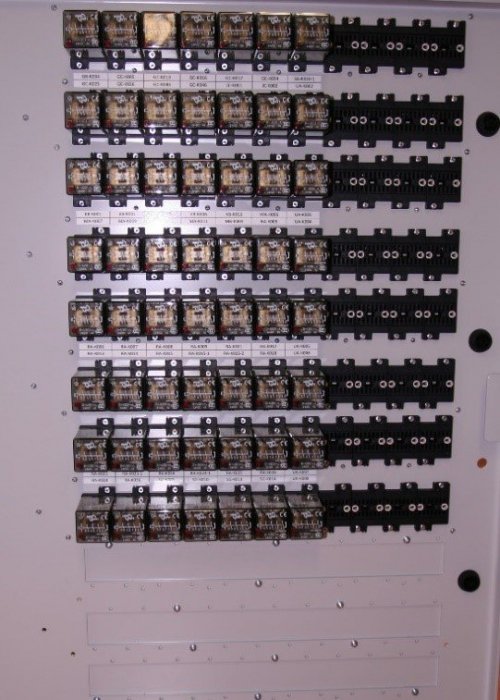

- A second modular panel with 54 D-U standard relays with 216 C/O contacts.

|

|

General features

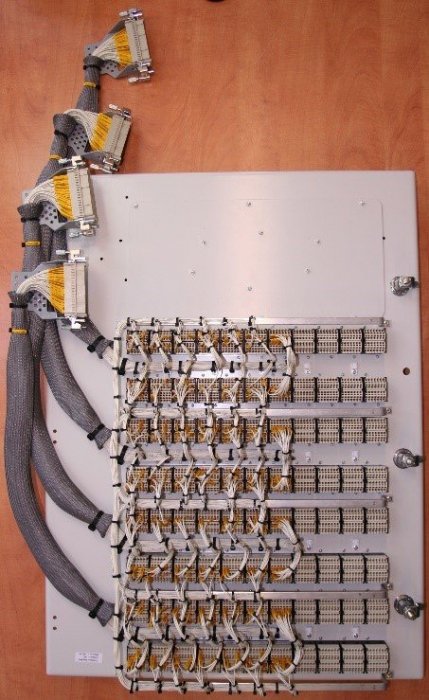

- All contacts are backside connected. The train wiring is connected through connectors with keying code, ensuring easy and correct installation and replacement.

- Earth connection of the panel is carried out via hinges of the panel.

- Wiring made in harness form, each wire is provided with unique coding.

- Easy marshalling / cross wiring inside the boxes enables last minute changes to the circuitry.

- Connections are wired, not on PCB, enabling 10 A continuous current on ALL circuits.

- The relays are plugged in a special socket, making it fast and easy to exchange, even to change into a timer or latching relay.

Why Mors Smitt

These HDRM panels are fully designed, manufactured and tested by Mors Smitt.

After manufacturing all units are 100% functional tested using our sophisticated test computer:

- Point-to-point wired connections

- 1000 VDC insulation test on all connections and wiring

- 100% fully functional test according schematics